AUTOMATED VERTICAL STORAGE

ASRS technology offers both floor space savings and productivity improvement. In many cases this equipment can reduce or even eliminate the need for a forklift. Every industry, customer, and application has its unique application challenges - ReSolve offers a broad solution base of automated storage and retrieval systems to best fit your process needs and to maximize your return on investment.

Your inventory profile and volume, combined with throughput and transactions needs will determine which type, size, and count of equipment is most appropriate - Contact ReSolve to discuss your application and arrange a complimentary in-person or web-meeting site survey.

Vertical lifts

Vertical Lifts operate with 1) Movement Section, referred to as the elevator or extractor, and 2) Storage Section. This vertical and horizontal movement helps you utilize vertical facility space without the need for mezzanines, man-lifts, or forklifts. Floor space savings from 70-90% can be achieved with vertical lift systems, while also improving safety and ergonomics for your team. By reducing the need for peripheral handling equipment as well as your personnel walking / searching for inventory, productivity gains from vertical storage systems can be significant.

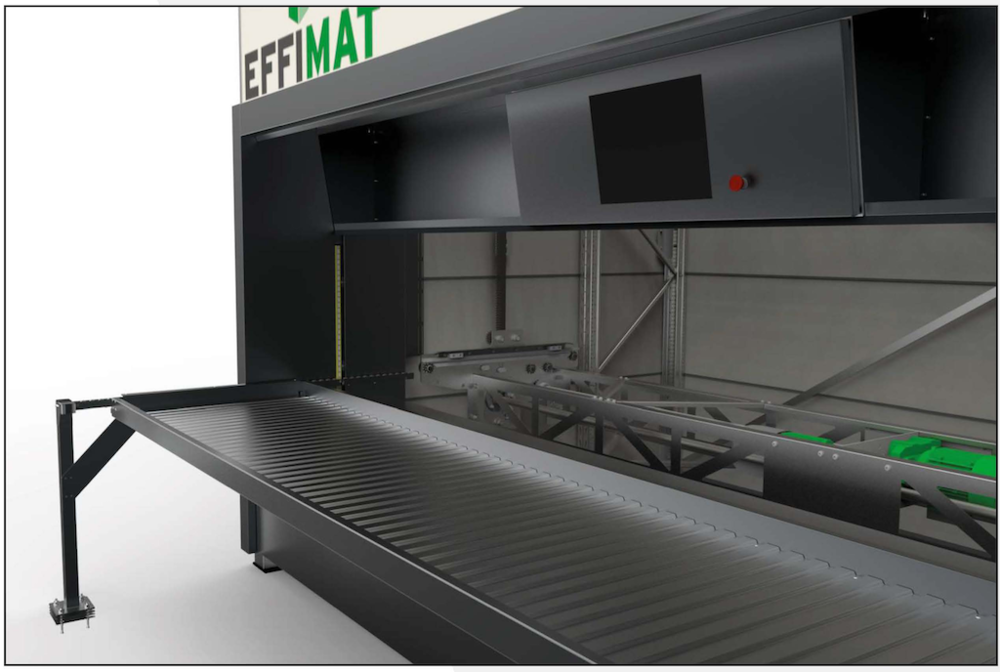

FULFILLMENT, ECOMMERCE, KITTING LIFTS

If speed is one of your primary goals, this order processing solution can output 250 Boxes Per Hour. Compare this to traditional vertical pan lifts that produce around 75-85 Pans Per Hour.

Options Include: Full ERP integration, multi-unit configurations, automated loading with conveyance, coordination with autonomous mobile robots.

Best Uses: Fulfillment, Order Processing, Kitting, Small Parts Management, Buffer Module for Distribution.

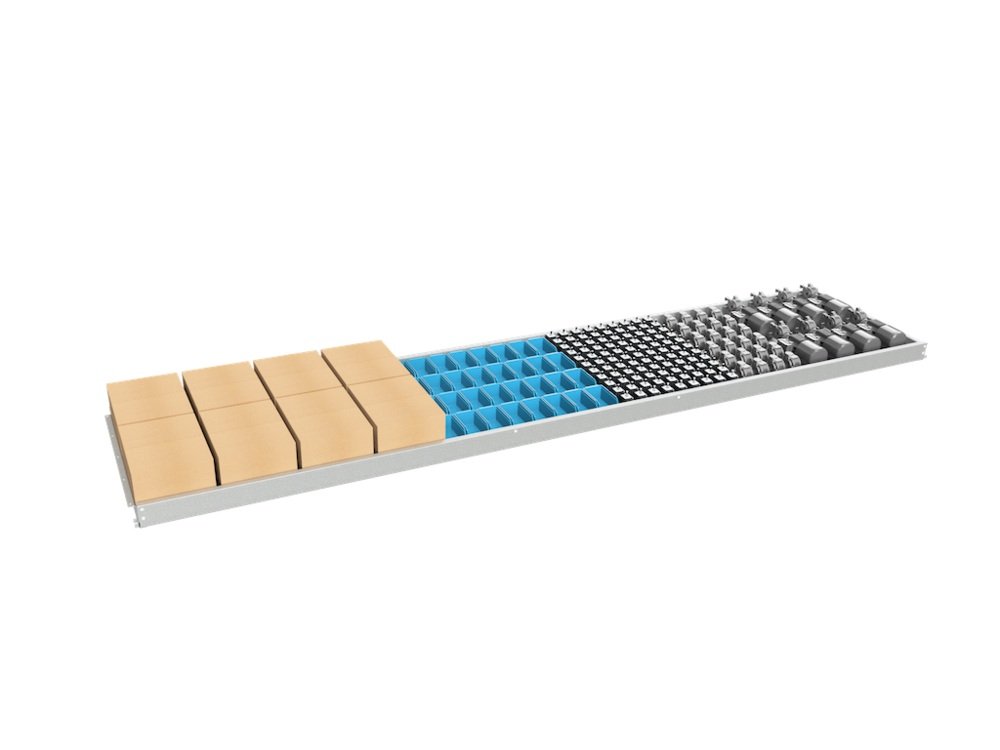

TRADITIONAL VERTICAL PAN LIFTS

If storage density is your primary goal, a traditional vertical pan lift will condense your inventory footprint while bringing improved inventory control and security.

Options Include: Full ERP integration, external tray position, widths up to 158”, overhead light pointer.

Best Uses: Storage of varying inventory sizes - small, medium, large, long all in one machine; Tool Storage, Parts Rooms, Maintenance Department.

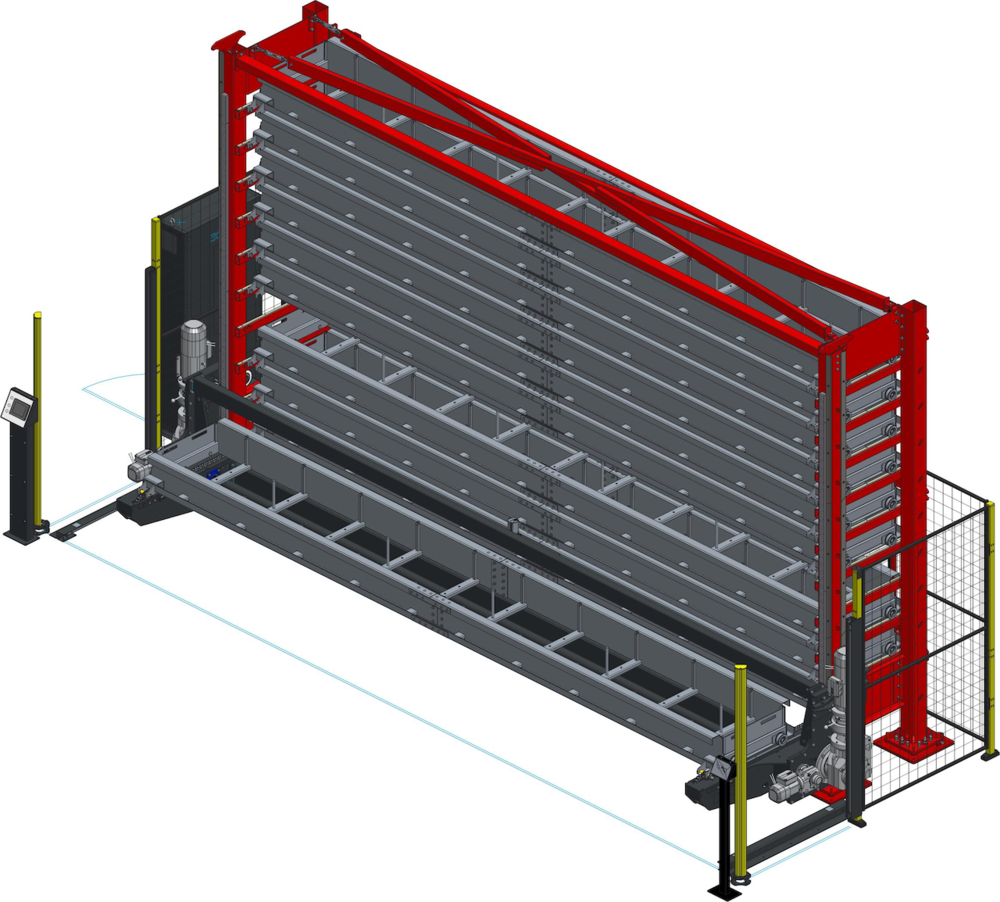

SHEET METAL & BAR STOCK LIFTs

With 5,000lbs capacity per shelf/drawer, this goods to operator system is built for heavy duty applications. Storage and handling typically performed by a forklift to/from pallet rack or cantilever can be streamlined with automated vertical storage lifts.

Options Include: Loading tables, automatic carts, and overhead handling solutions like jib cranes, trolley cranes, and monorails.

Best Uses: Sheet Metal, Bar Stock, Tube Stock, Fiberglass, Plywood, Fabrication Support, Laser Cutting Operations

VERTICAL CAROUSELS

Automated vertical carousels operate with a rotating ‘ferris-wheel’ principal, maximizing use of overhead storage within your facility. Carriers or Shelves rotate bidirectionally within a track system to store and retrieve inventory. This simple, robust, concept has been around for 70 years and offers a very reliable platform for various inventory types. This style of ASRS can pack a lot of storage into a small area and is applicable even at shorter ceiling heights. Shelves are delivered to an ergonomic waist height and eliminates the need for bending, stooping, ladders, or order pickers. Stand alone systems with onboard controls can keep implementation extremely simple - there is always the opportunity for integration with your ERP for improved order processing efficiency and inventory tracking.

PAN CAROUSEL

Space savings, productivity improvement, inventory control, inventory security, and ergonomics all from one system. This fully enclosed system offers the highest protection for your inventory and the highest inventory density.

Options Include: Intermediate shelves, totes, inventory location management, job processing, carrier widths, depths, and heights to match your application

Best Uses: small parts and/or consistently sized items; maintenance departments, spare parts at auto or truck dealers, electronics, low volume high variability applications.

BULK MATERIAL CAROUSELS

Back stock or larger boxes and bulk items or raw materials can be accommodated in a vertical carousel tailored for that inventory type. Take advantage of automatically storing and retrieving inventory that can be cumbersome to handle or access.

Options Include: Mezzanine level access, widths, depths, heights to meet your space requirements.

Best Uses: Wire spool processing, tire storage, boxed inventory, carpet rolls, vinyl rolls.

MORE APPLICATIONS

DISTRIBUTION CENTER PROCESSING

TRADITIONAL VLM VS BOX MOVER

E-GROCERY / MICROFULFILLMENT

STATIC SHELVING VS AUTOMATION

Get Started

Schedule a site-survey today.